Because of a few minor errors in the original article we publish a rectification of the article Shaping Building Surfaces from Roel Schipper in Rumoer 56 online on our website.

Download the article here, or read below.

SHAPING BUILDING SURFACES

Inspired by Renzo Piano

Written by Roel Schipper, TU Delft, Faculty of Civil Engineering and Geosciences

It was in October 1969, only one year after my first birthday, that a remarkable series of lectures took place in Delft . Structural Engineering professor Jaap Oosterhoff had invited a number of esteemed foreign guests to lecture concerning the intriguing theme “Plastics in load-bearing structures”. You should know that, at that time, plastics were the booming material, promising to solve many problems in the world which is illustrated perfectly by a line of the lyrics of I.G.Y., a song from the famous album ’The Nightfly’ of Donald Fagen: “… Here at home we’ll play in the city, powered by the sun. Perfect weather for a streamlined world, there’ll be spandex jackets one for everyone. What a beautiful world this will be…“ The lecturers were pioneers and authorities on the developments of spatial structures, such as professor Frei Otto and ir. Piet Huybers, some material experts in the field of plastics, such as professor Makowsky and Dr. Niederstadt, and a rather unknown Italian architect and researcher, dottore Renzo Piano.

Renzo Piano, having his own studio and at the same time working at the Polytechnic University of Milan, in the years between ’64 and ’69 had designed, manufactured and constructed a number of amazing light-weight spatial structures in plastic, using various innovative techniques that, at that time, were unseen elsewhere. The innovations concerned at least four aspects of his work:

- the remarkably freely formed shapes of his designs

- the used building materials, such as fibre glass (a glass-fibre reinforced matrix of polyester), polyethylene and polyurethane foam

- the structural models, using square-based pyramidal elements, barrel vaults, tensioned grid membranes and pneumatic structures

- the shaping and manufacturing techniques, such as vacuum pulling, casting, glueing and melting.

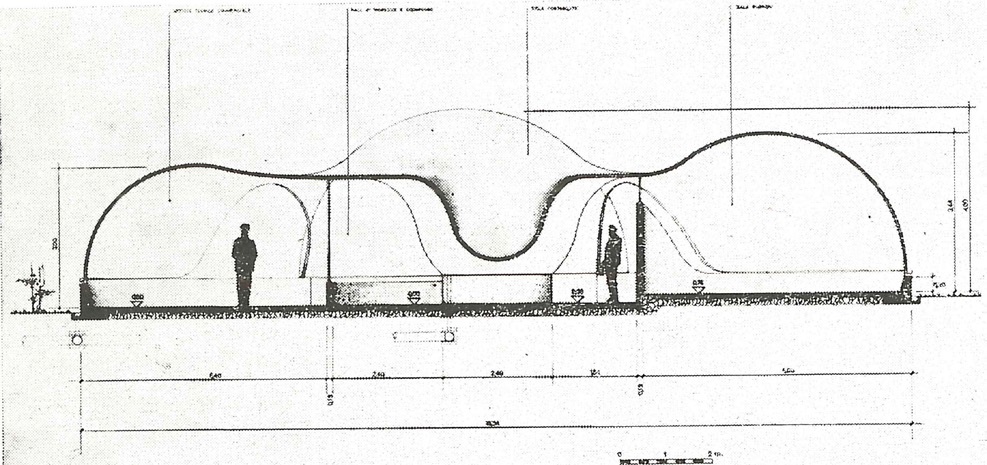

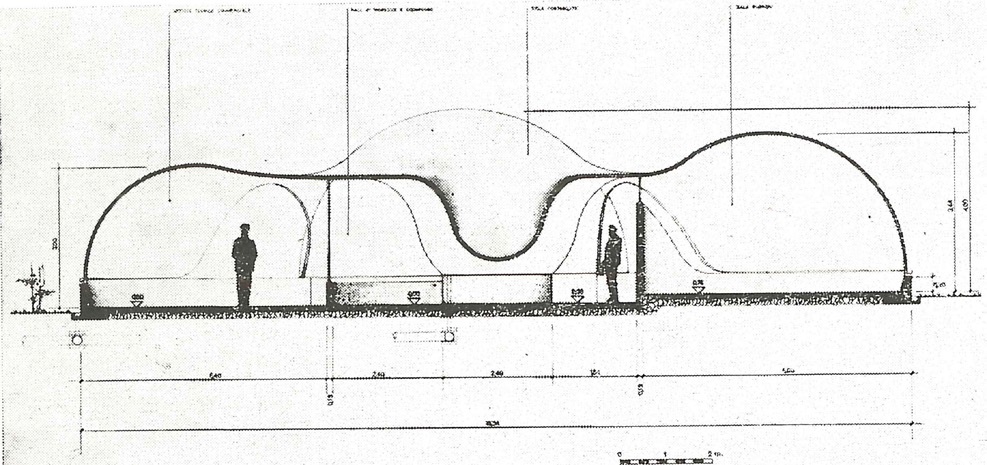

From the lectures described in the reader of Oosterhoff (1969), one article specifi cally intrigued me: it is a reprint of a publication in the Italian architecture journal Casabella with the title “Experimental project of shell structures” (Piano1969). It contains the quite detailed description of a manufacturing method for plastic 3D elements to use in free-form pavilions, such as the one shown in Figure 1 and 2. Visible is an example of a 4 meter high, 17 meter long pavilion, consisting of three connected domes. Realizing that this shape would challenge the available manufacturing techniques, Piano also developed himself an innovative machine, which he named “stampo deformabile” or “deformable mould”, shown in Figure 2. This machine was able to read from a scaled model of a free-form building (shown on the left table in Figure 2) the building height at a grid of x-y-coordinates, and translate this to full-scale panels manufactured in plastic (shown on the right table in Figure 2), a sort of 3D-printing avant-la-lettre.

By using the manufactured plastic 3D-elements, Piano constructed a number of experimental pavilions, for example the one shown in figure 2. The reason that the article was so intriguing, is that the manufacturing of 3D double-curved elements is the central theme of my own PhD research. Before starting with the PhD, I already found the image of Piano’s stampo deformabile in publications, but without the complete description and background. Piano’s work is actually still very much up-to-date: mass-customized production of double-curved freeform elements is generally regarded only possible after the realization of a flexible mould system: an adjustable formwork consisting of an elastic material that can be formed into any curved surface by the use of pistons, actuators, pin beds or the like Munro and Walczyk (2007). On this elastic formwork the actual building element can be shaped, either by casting a hardening material such as concrete on the formwork, or by depositing a material that can be softened, such as a sheet of heated thermoplastic or glass. After the building material has taken the form of the formwork and is hardened or solidified, e.g. by hydration or cooling down, the shaped building elements is ready for use. The flexible mould can be reused for another element, possibly with a different shape.

Figure 5a: Prototypes of Dr. Karel Vollers and ir. Daan Rietbergen (left) and Peter Eigenraam, MSc (right) Photo: R. Schipper

Figure 5b: Prototypes of Dr. Karel Vollers and ir. Daan Rietbergen (left) and Peter Eigenraam, MSc (right) Photo: R. Schipper

A few years ago, researchers from the Faculty of Architecture Dr. Karel Vollers and ir. Daan Rietbergen developed and patented a flexible mould principle (Vollers and Rietbergen, 2008) Figure 5. When I got involved in the MSc-thesis work of two students of Dr. Vollers, trying to manufacture double-curved elements in concrete, I decided that the further development of this method would be a perfect PhD study

topic. In the past year a considerable amount of time has been spent on further overthinking and improving Piano’s concept, especially for the building material concrete. MSc students Peter Eigenraamand Marijn Kok of the Faculty of Civil Engineering and GeoSciences, MSc-track Building Engineering, have been working on the mould system respectively the material properties for this particular way of producing curved concrete elements. Resulting in a gradual improvement and practical realization of the idea in working prototypes.

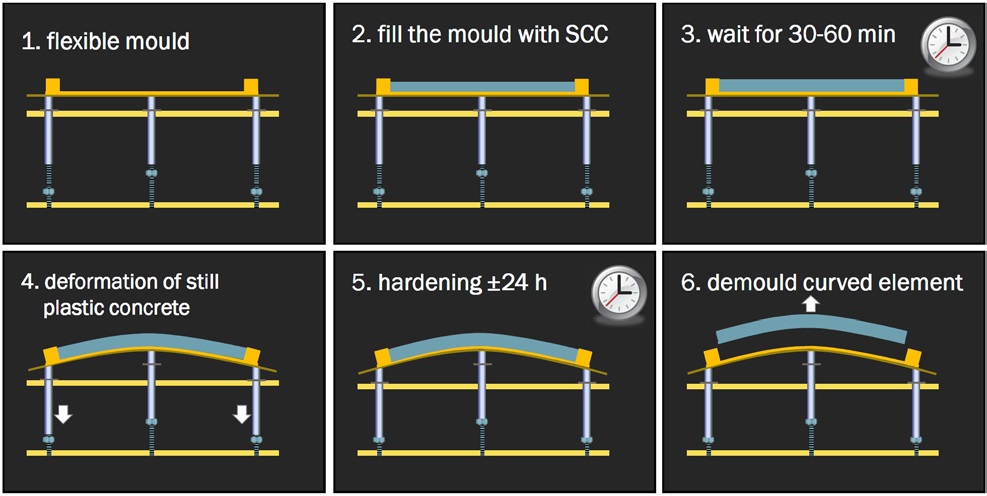

In the Stevin lab, several experiments have been conducted to find out the right concrete mixture and the accuracy of the shaping method. In Figure 4 the principle is explained step by step: The flexible materials of the mould are supported by a subsystem controlling the desired final shape (step 1). The mould is filled with self-compacting concrete (SCC, step 2); fibres or textile can be used as reinforcement. During a short period of structural build-up, the yield strength of concrete increases (step 3). Then the mould is carefully deformed into its final shape (step

4). During this deformation, the fresh concrete has to follow the strain and stay stable under a certain slope. Concrete hardens in the deformed mould (step 5) and finally the element is demoulded (step 6). The flexible mould can be reused to produce more elements, with identical or with altered curvature and geometry.

The test setup and a number of elements are shown in Figure 6 on the next page. Visible is a setup of four flexible moulds, supported by flexible lathes (top image). This setup was used to do a parameter study on concrete mixture, curvature and deformation process. In the lower two images in Figure 6 on the next page a series of (single) curved elements is visible. The process of deforming concrete aft er casti ng proved to be a feasible method, leading to accurately shaped panels with sufficient strength in a relatively simple way.

Also internationally, progress has been made in the development of the flexible mould: Adapa, a Danish firm, has built a prototype that also allows manufacturing of curved elements (Raun and Kirkegaard, 2012). The main issue, both in Adapa’s research and mine, appears to be the exact control of the shape of the mould surface. A NURBS-surface drawn in Rhinoceros 3D does not automatically translate to the exact and similar surface in the mould, since the weight of the concrete and the elasticity of the flexible surface lead to various effects that are difficult to understand and predict. Making laser-scans of the elements (see Figure 7) has demonstrated that an acceptable accuracy can be reached, but that the congruent joining of the edges of elements requires more attention and thinking.

Perhaps the main reason that the flexible mould did not yet see its massive breakthrough in architecture, might be the fact that understanding and controlling the method requires a mix of various fields of expertise. These are often not found in one person: knowledge of machine building, free-form architecture, complex geometry, computer scripting and concrete, plus the skills to sell the idea to parties that might be able to fund further research and developments. Maybe an -until now- rather unknown Dutch architecture student and researcher could fulfill this role?

References

- Chris Munro and Daniel Walczyk. Reconfigurable pin-type tooling: A survey of prior art and reducti on to practi ce. Journal of Manufacturing Science and Engineering, 129(3):551–565, January 2007. ISSN 1087- 1357. URL htt p://dx.doi.org/10.1115/1.2714577.

- J. Oosterhoff, editor. Kunststoffen in dragende konstrukties – een verzameling tijdschrift artikelen, gebundeld ten behoeve van de leergang “kunststoffen in dragende konstrukties” op 17 en 17 oktober 1969 te Delft, 1969. Stichting Post-Doktoraal Onderwijs in het Bouwen.

- Renzo Piano. Progettazione sperimentale per strutture a guscio – experimental project of shell structures. Casabella, 335:38–49, april 1969.

- C. Raun and P.H. Kirkegaard. Reconfigurable double-curved mould. In J. Orr, M. Evernden, A. Darby, and T. Ibell, editors, Proceedings of the Second International Conference on Flexible Formwork, ICFF, pages 292–299. CICM and University of Bath, Dept. of Architecture and Civil Engineering, 2012.

- K.J. Vollers and D. Rietbergen. A method and apparatus for forming a double-curved panel from a flat panel, 2008.

Roel Schipper, MSc graduated in 1993 at Delft University of Technology, Faculty of Civil Engineering, chair of Building Engineering. In 1994 he became a junior consultant Building Physics at Van Dorsser Raadgevende Ingenieurs in The Hague. In 1997 he joined Ingenieursbureau Concretio, a structural engineering firm in Zwijndrecht, The Netherlands. Leaving the field of building physics, he worked on the full width of structural engineering. Since 2008, he is working as lecturer/researcher, lecturing a.o. structural and building engineering. He is now finishing a PhD research which focuses on the manufacturing of precast double-curved concrete elements.